This project explores the use of a physical floor plan of The Peranakan Museum (TPM) to support curators and the production team in planning future exhibitions. It includes miniature scaled models of key exhibition elements such as plinths, paintings, and figures to visualise spatial arrangements effectively and optimise exhibition planning before production commences.

Purpose of Project

The project focuses on addressing a recurring challenge faced by curators and production teams: bridging the transition between the curatorial phase of an exhibition and production of it. The goal here is to ensure alignment between the production of the exhibition and the curator’s vision. Curators have highlighted the difficulty of visualising a 2D floor plan as a 3D space, especially when the plan lacks volume or spatial references, making it challenging to imagine the final layout without real-world context.

Current Approach

The current use of 2D floor plans to curate exhibition spaces presents several challenges. Without depth or volume, they make it difficult for curators to visualise how artworks will inhabit the space, leading to uncertainty around scale and impact. Key spatial relationships—such as distance, sight lines, and visitor flow—are easily misjudged. The lack of a shared 3D reference can hinder communication between curators and production teams, resulting in design outcomes that diverge from the intended curatorial vision.

Proposed Solution

The proposed solution is to produce a 3D-printable physical floor plan in-house, enabling the team to respond to structural or layout changes without relying too much on external vendors. To aid curators in visualising spatial arrangements, the model will feature miniature elements such as plinths and platforms, offering a clearer understanding of object placement and scale within the exhibition space. This approach can negate misalignment between curators and production teams.

Project Requirements

The TPM museum floor plan will feature a base plate that secures modular, swappable parts. Miniature components will include figures, plinths, and partitions, all colour-coded for clarity that can be moved around the floor plan with magnets embedded on the bottom of the floor plan. Walls will be 6cm high, representing a real-world height of 3 metres. A dedicated storage unit will house all elements, making the set portable and easy to manage. The unit will also include a mechanism that enables side-by-side comparison of two different floor plan configurations.

Project Deliverables

1. A physical floor plan of the special exhibition areas on Levels 2 and 3 of TPM will be produced as one set, with two identical sets in total.

2. Each set includes a selection of miniature objects such as human figures, plinths, and modular walls, with four colour variations to test different colour combinations.

3. A storage cart with modular compartments will be built to house all components developed for the project.

Team Members

Bao Songyu

Ezekiel Wong

Muhammad Syahid Mustapa

Project Budget

S$5950

Scale of Floor Plan

One major consideration in the project was determining a suitable scale for the miniature floor plan. A scale too small reduces visual clarity, while one too large poses storage challenges, particularly given the museum’s limited space. All components must therefore fit within a single movable storage cart. Following a review of several options such as 1:300, 1:400, 1:500, and 1:600, the 1:500 scale was selected for its ease of translation and compatibility with the preferred wall height of 6 to 8 cm.

Thickness of wall

Another key consideration is the thickness of the walls in the miniature model. At a scale of 1:500, some partition walls would be too thin to replicate accurately or construct reliably. Although the overall scale is followed, certain elements, especially internal partitions, cannot be reduced proportionally. To resolve this, all walls in the floor plan will be set to a standard thickness of 4MM, unless stated otherwise, to ensure structural stability and visual consistency.

Material Selection

A holding plate is required for each floor plan set, and wood has been selected as the primary material due to its strength and ability to support a heavy magnetic base for magnetically attached objects. 3D printed alternatives were ruled out, as they lack the necessary durability. For the floor plan itself, PLA was chosen for its ease of printing and wider colour range, offering flexibility for future production of miniature components in various colours.

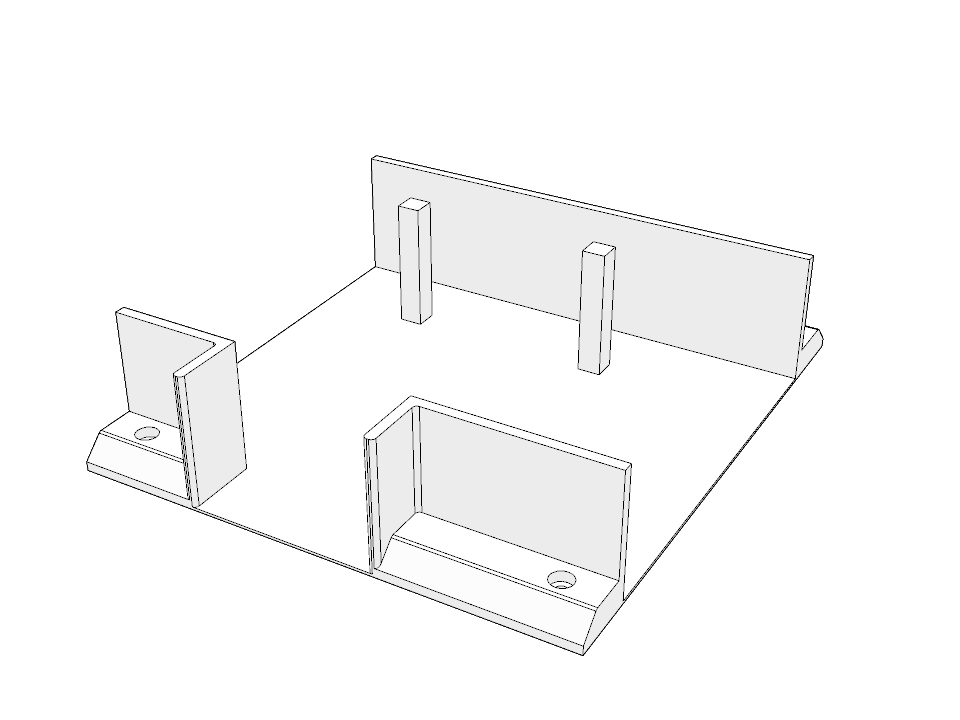

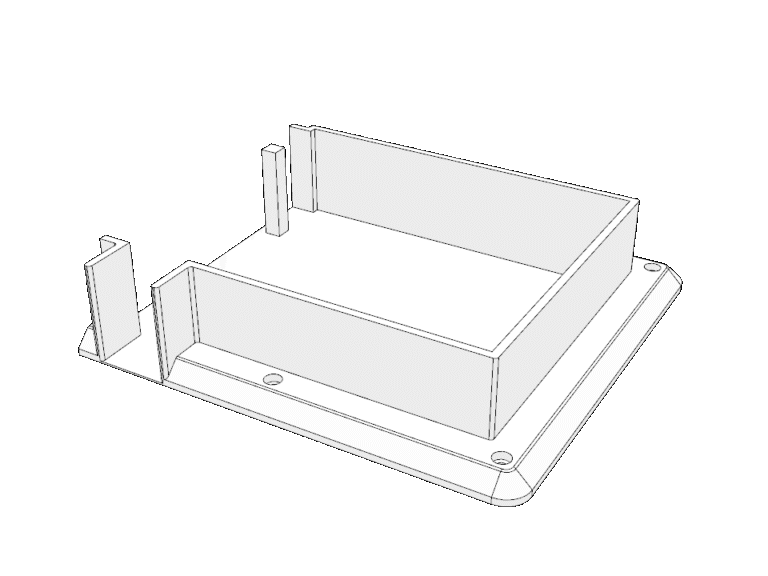

01

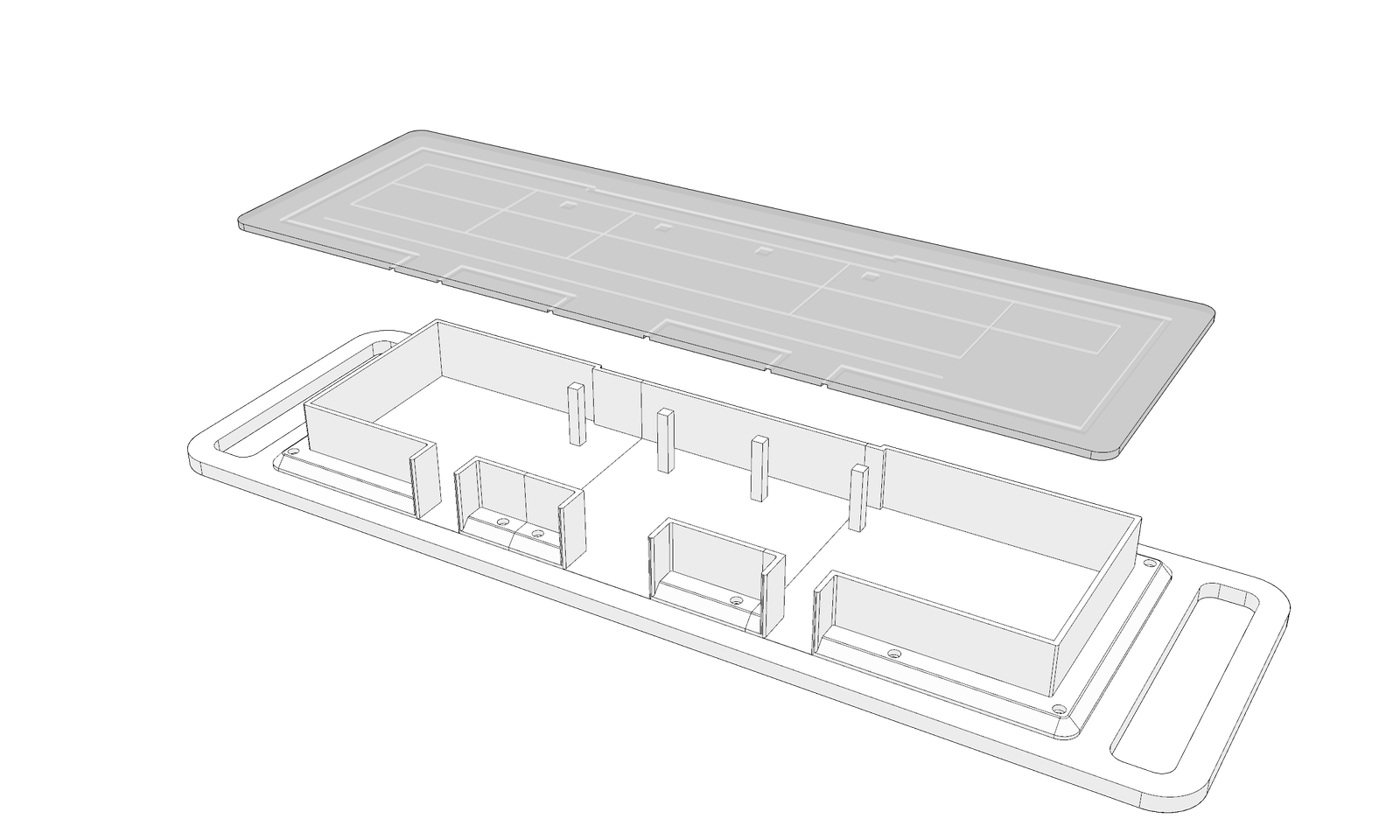

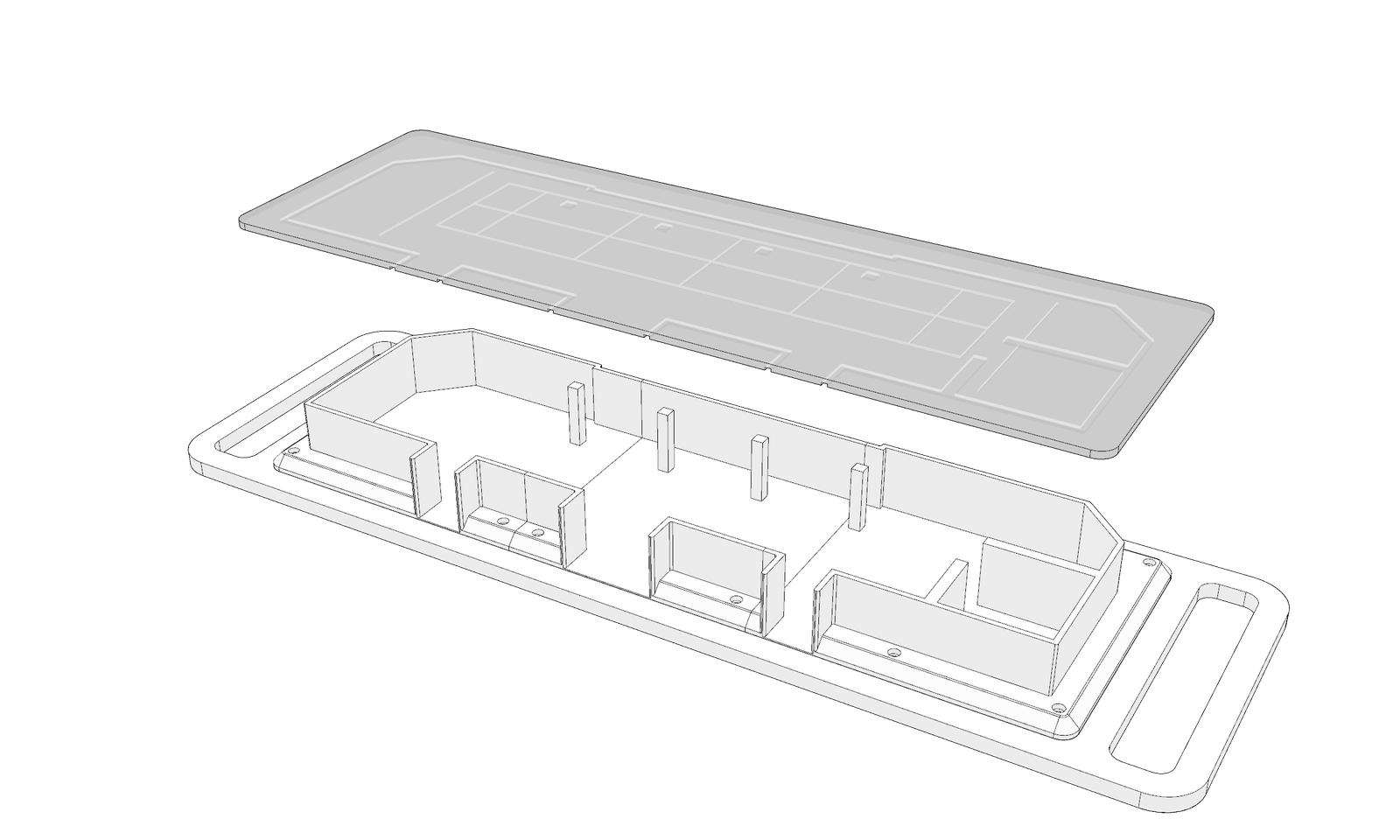

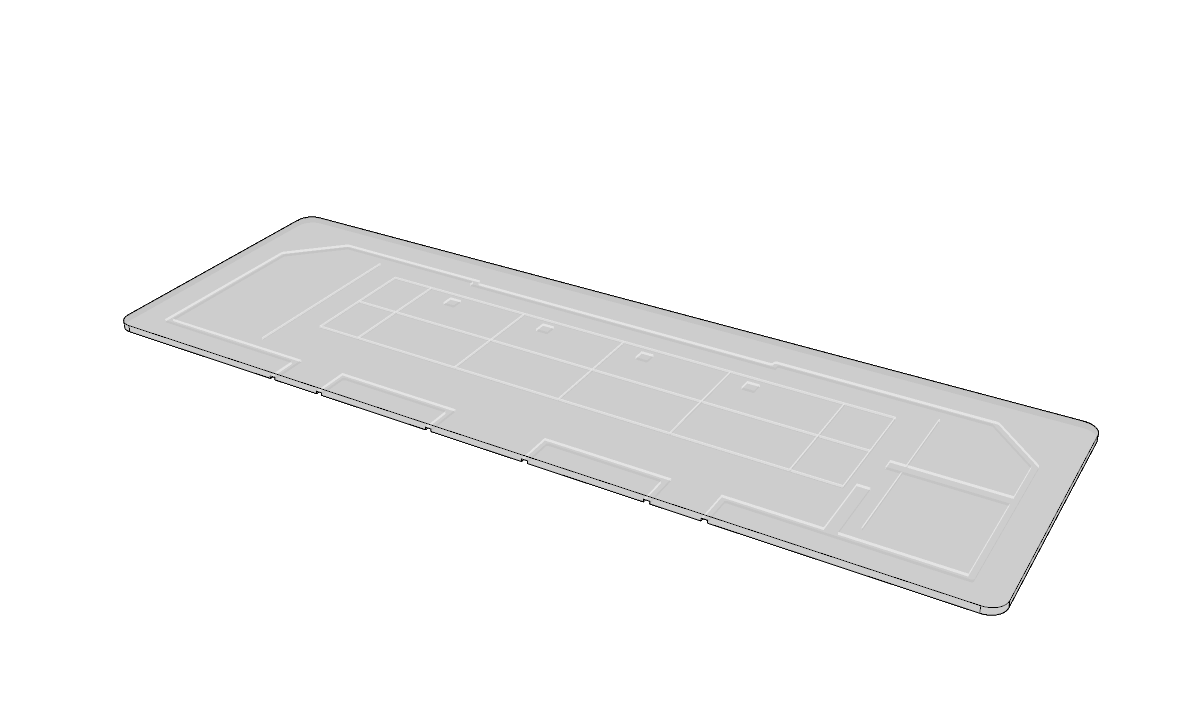

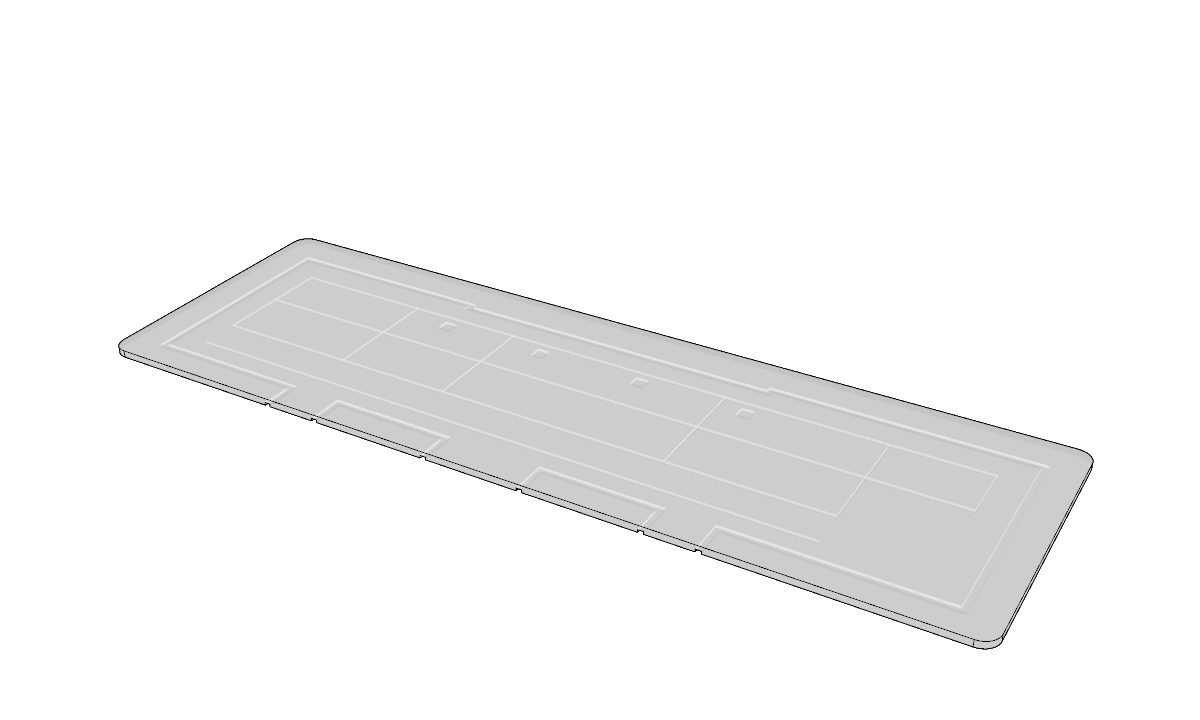

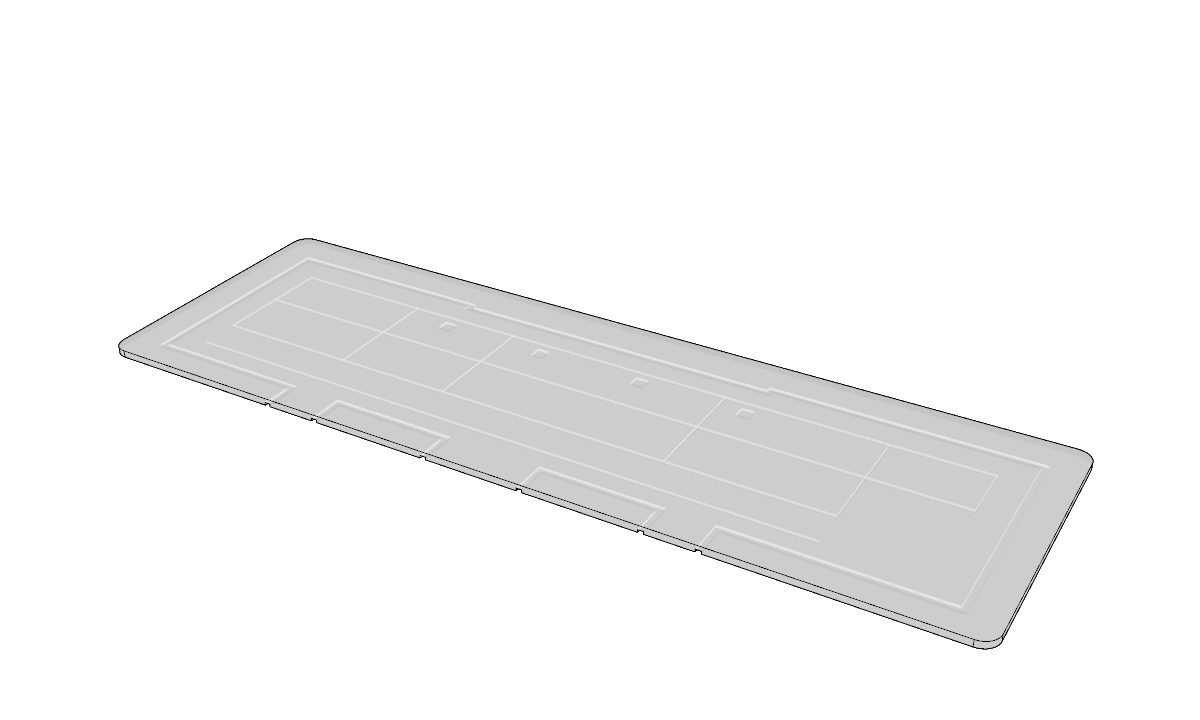

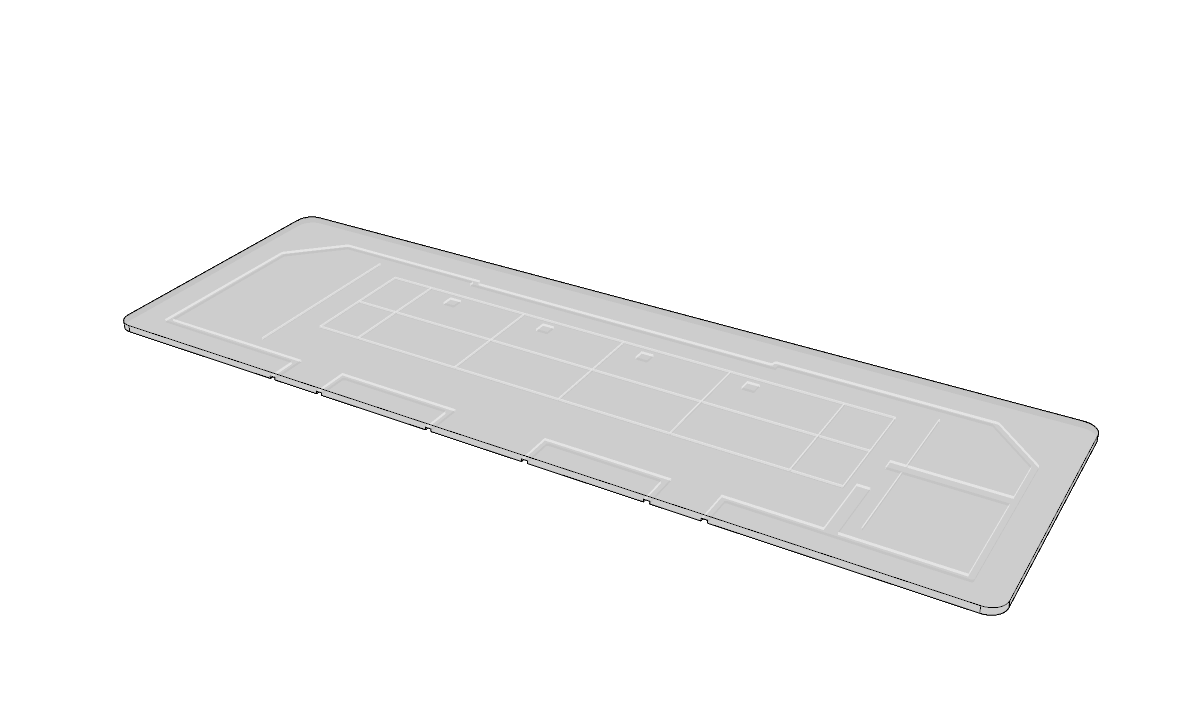

Detachable Acrylic Panel

This acrylic panel features the gallery’s lighting plan etched onto its surface. Its purpose is to help users visualise the placement of lighting within the gallery space, making it easier to plan and curate the exhibition effectively.

02

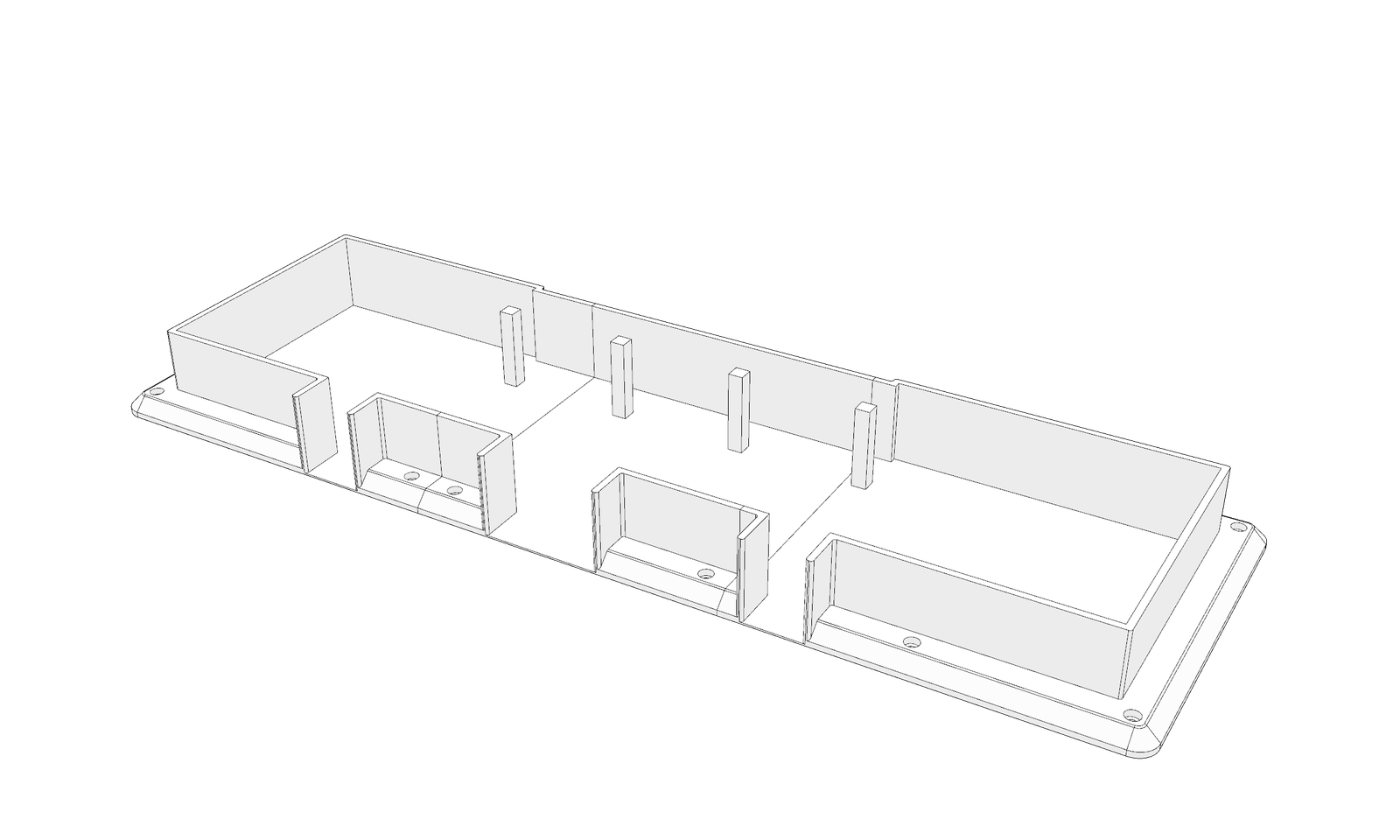

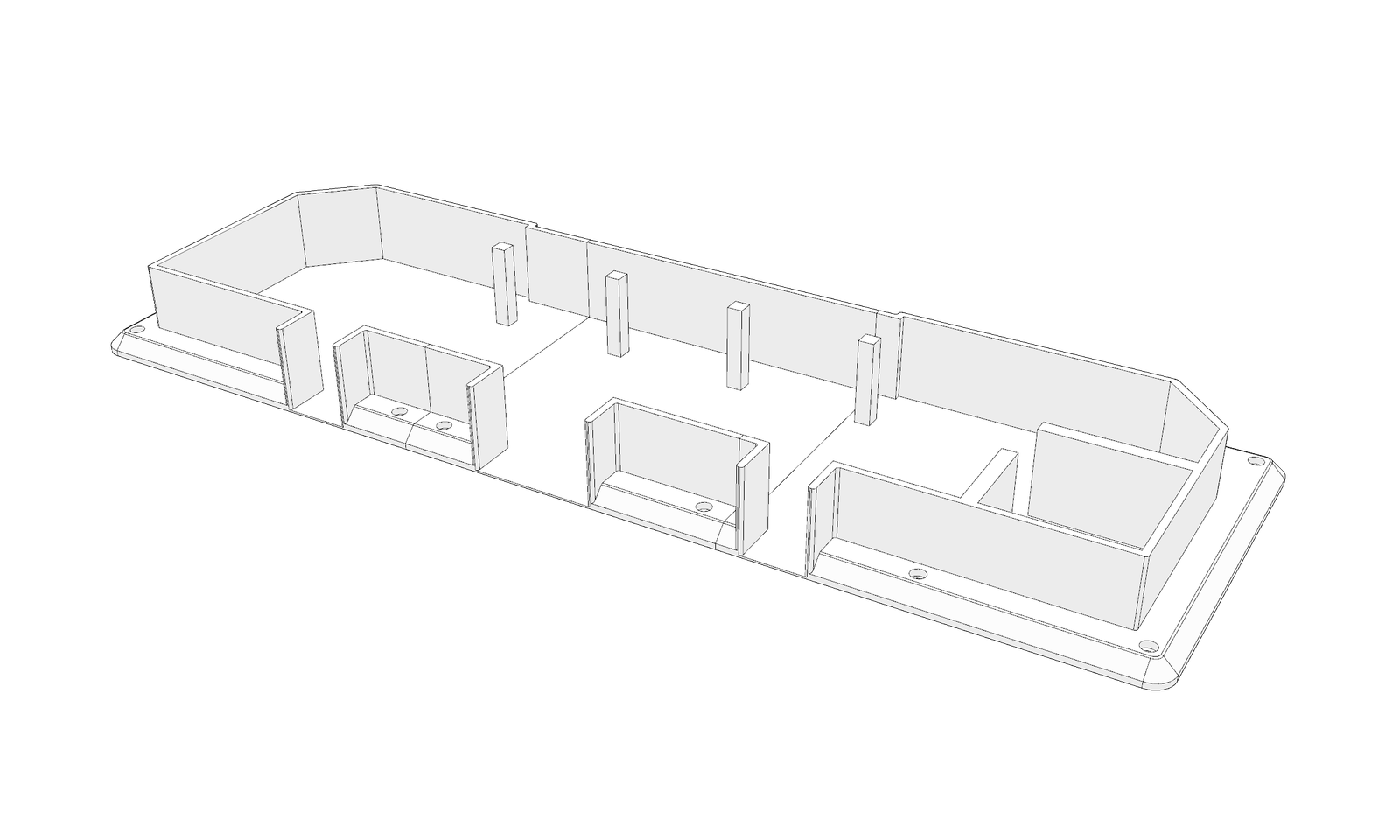

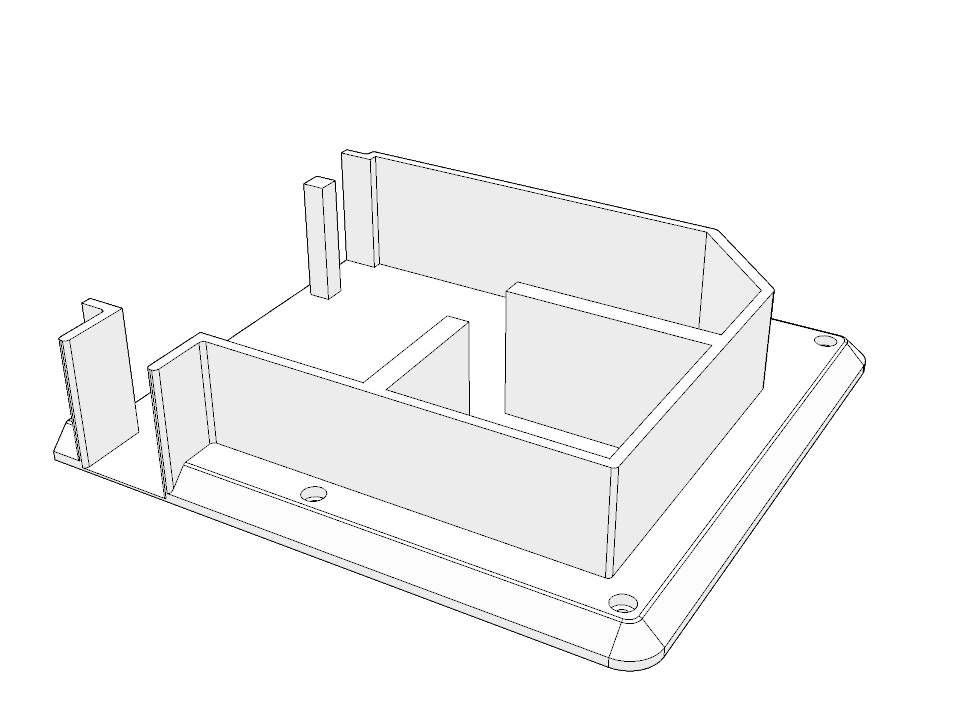

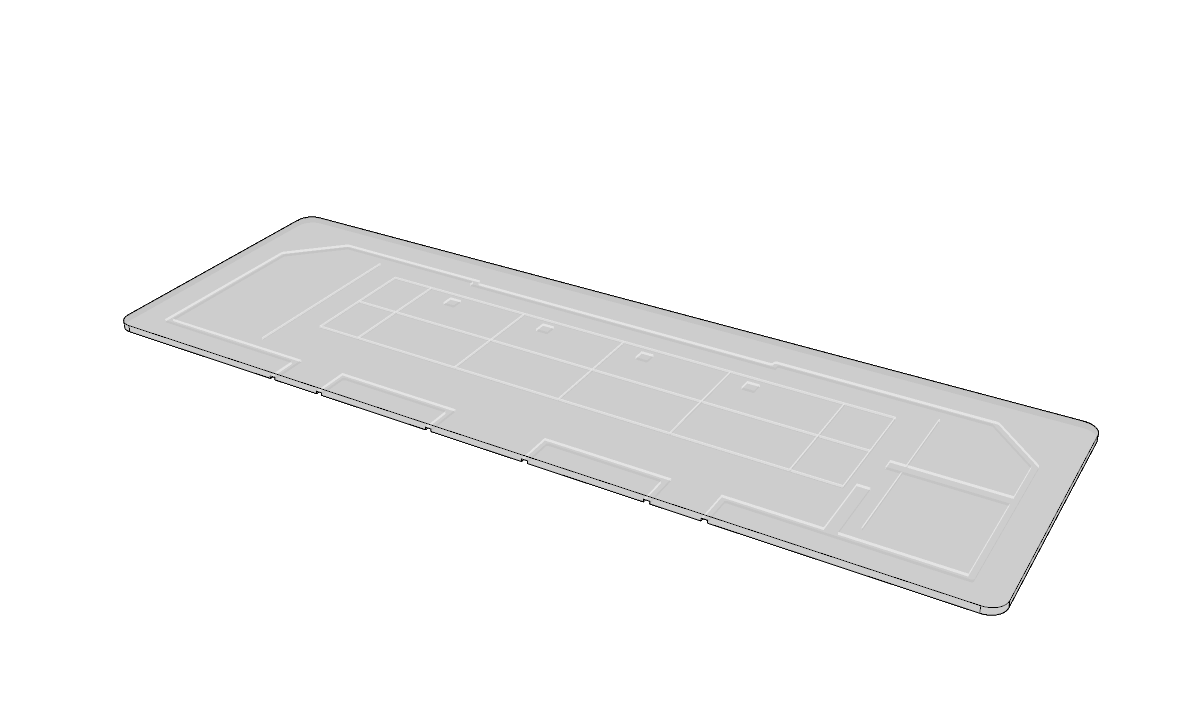

3D printed Floor Plan

This 3D printed floor plan design is modular and can be bolted and unbolted, allowing for updates in response to renovations or the incorporation of new, more permanent features within the gallery.

03

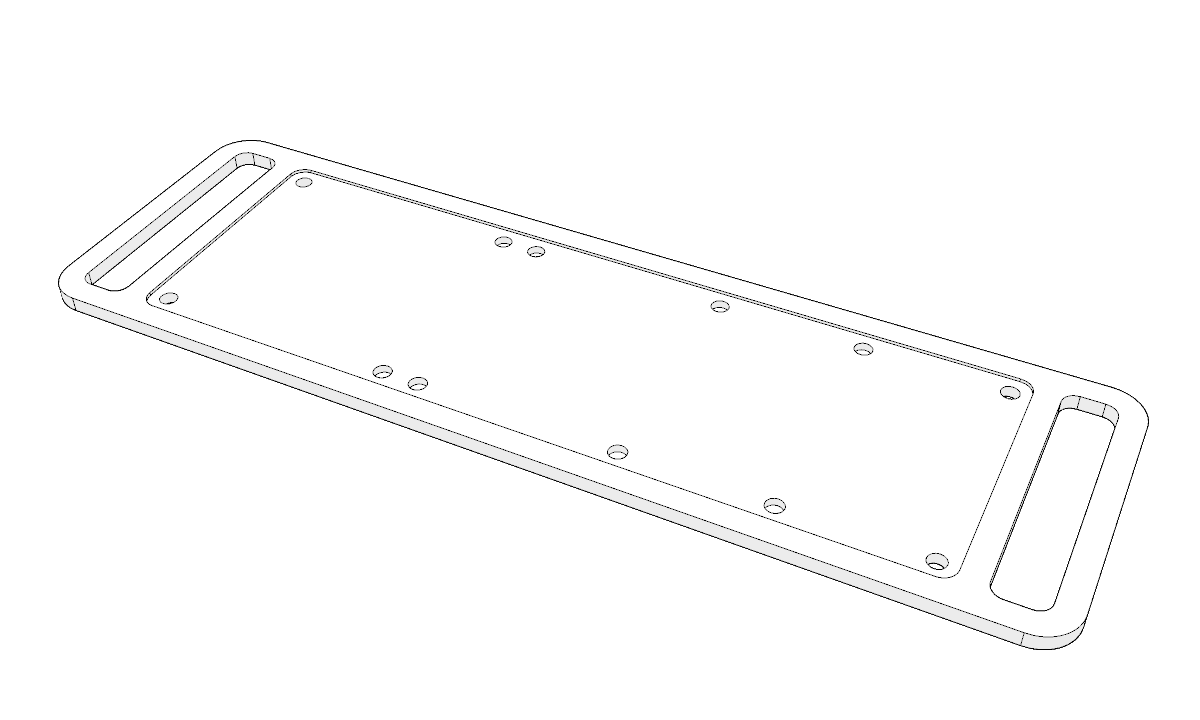

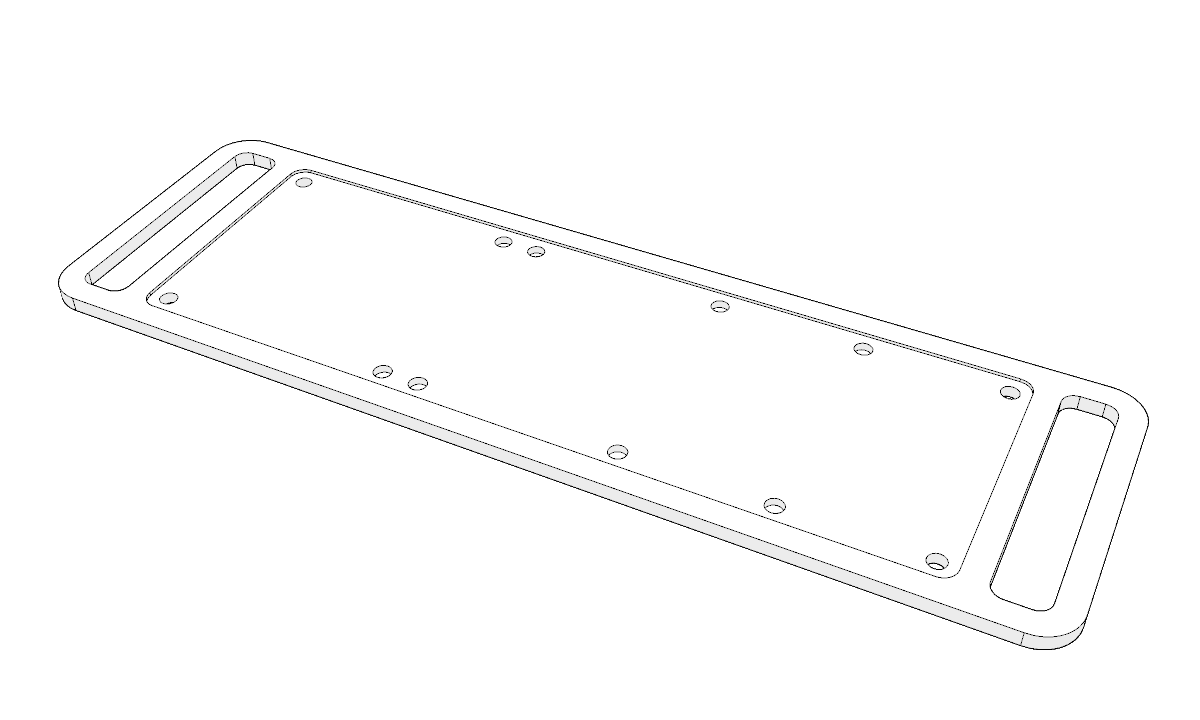

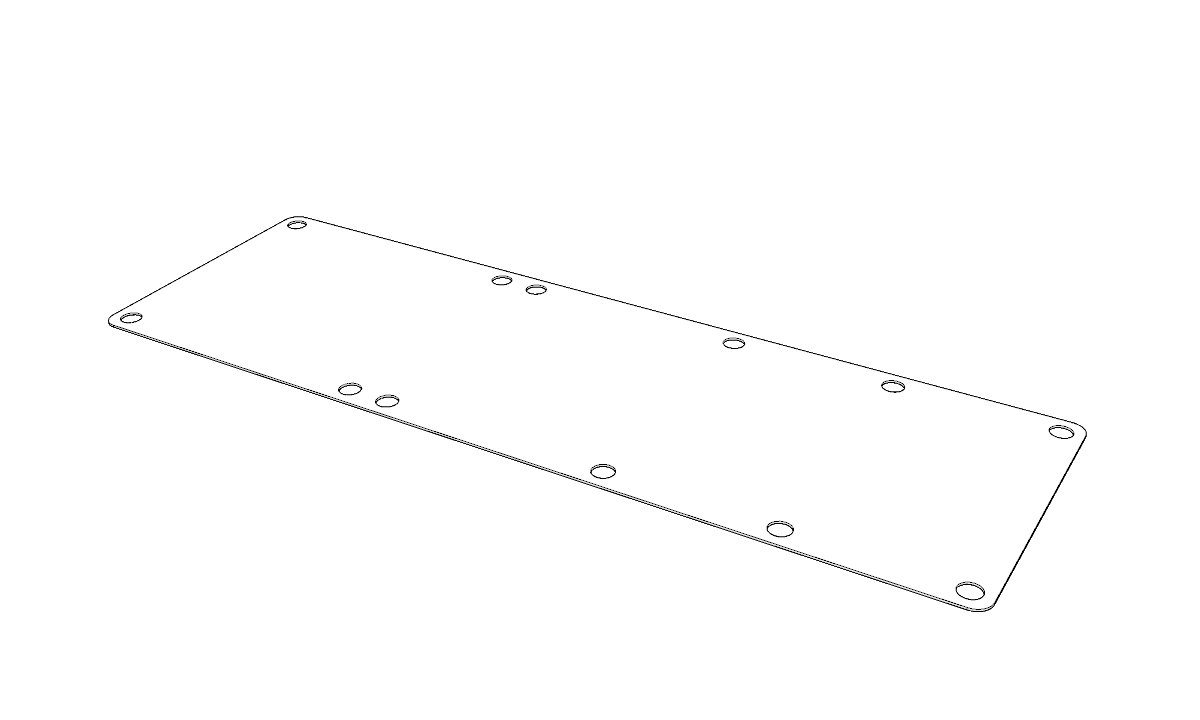

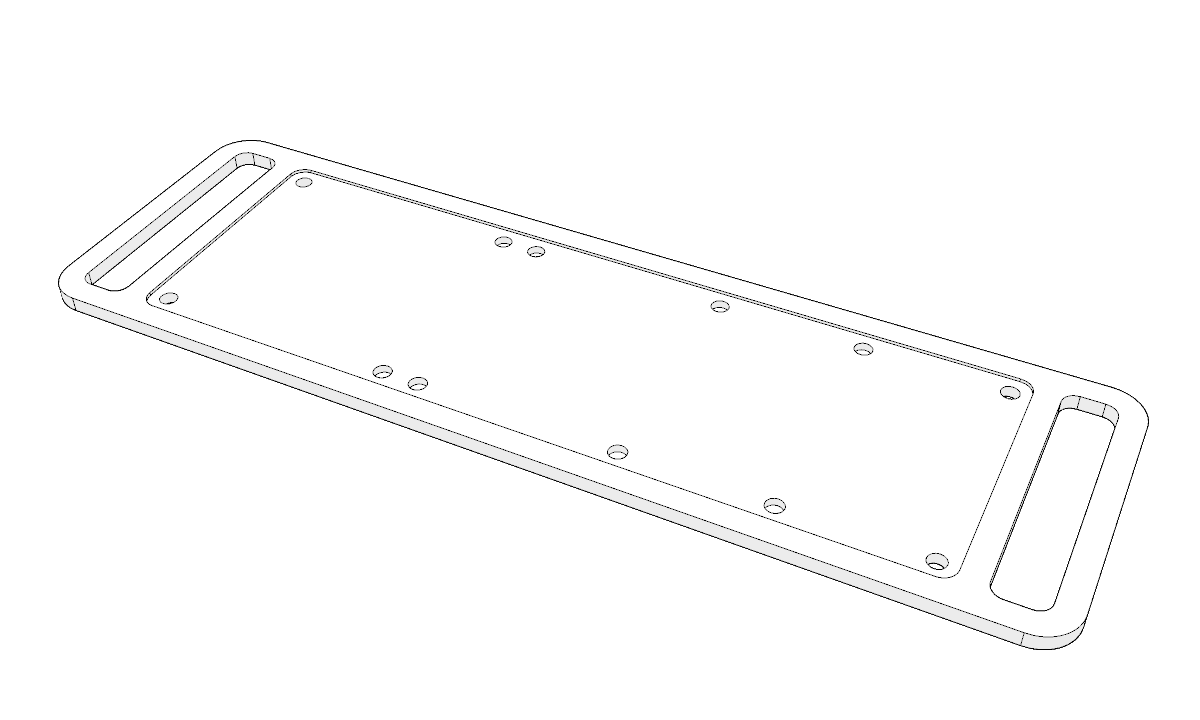

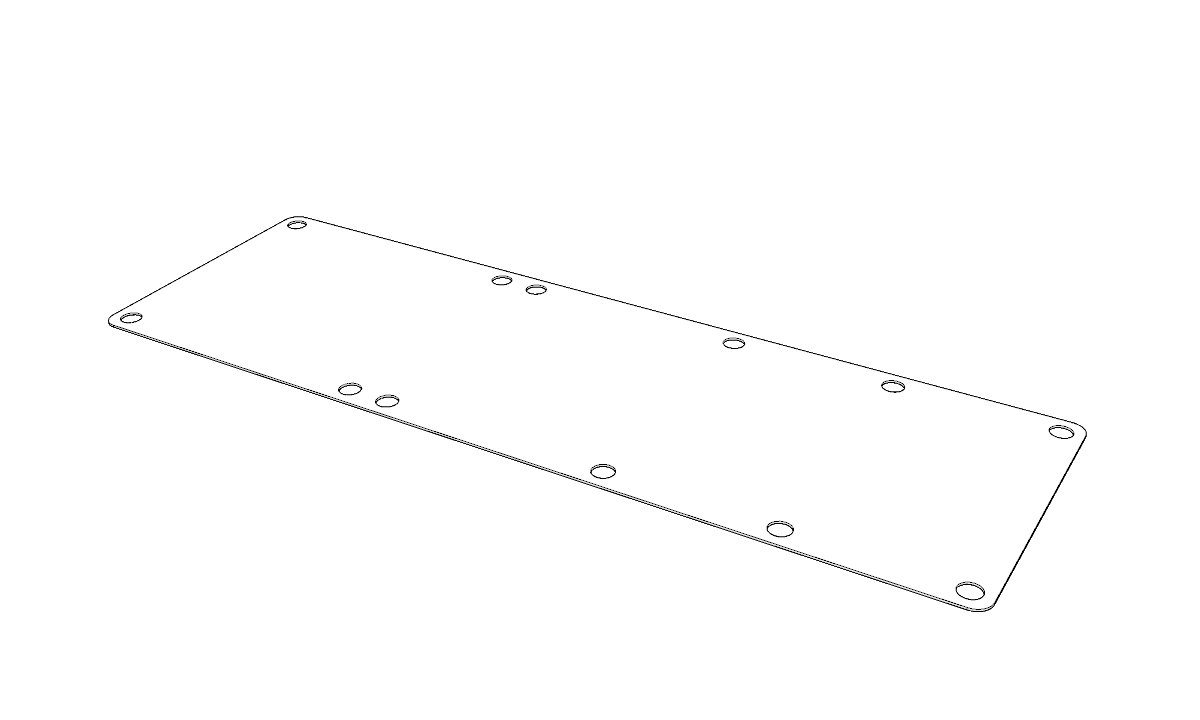

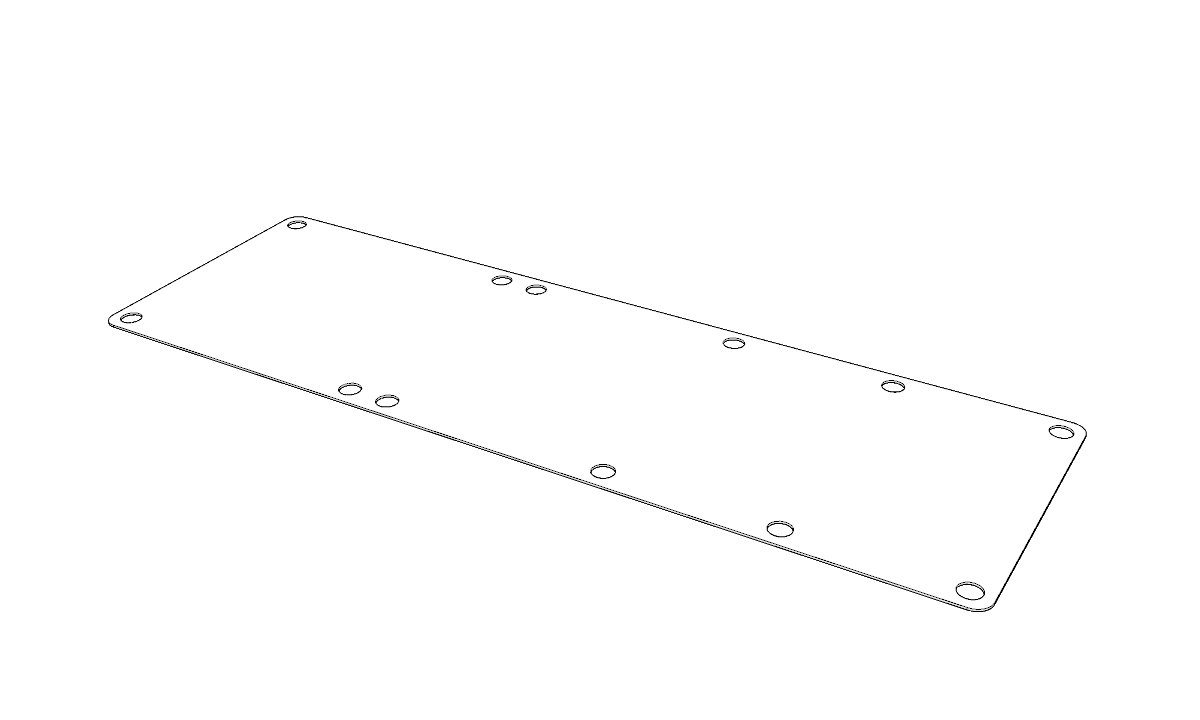

Wooden Panel

This wooden panel serves as the base of the entire floor plan structure. It provides foundational support, securing both the steel panel and the 3D-printed floor plan in place. Side handles are integrated into the panel design to facilitate easy transport.

Materials

3D Printed PLA

Stainless Steel Hardware

Wood Panel

Coated steel

Dimensions

800mm (Length)

250mm (Width)

650mm (Height)

Development Time

3 weeks

Design Goal

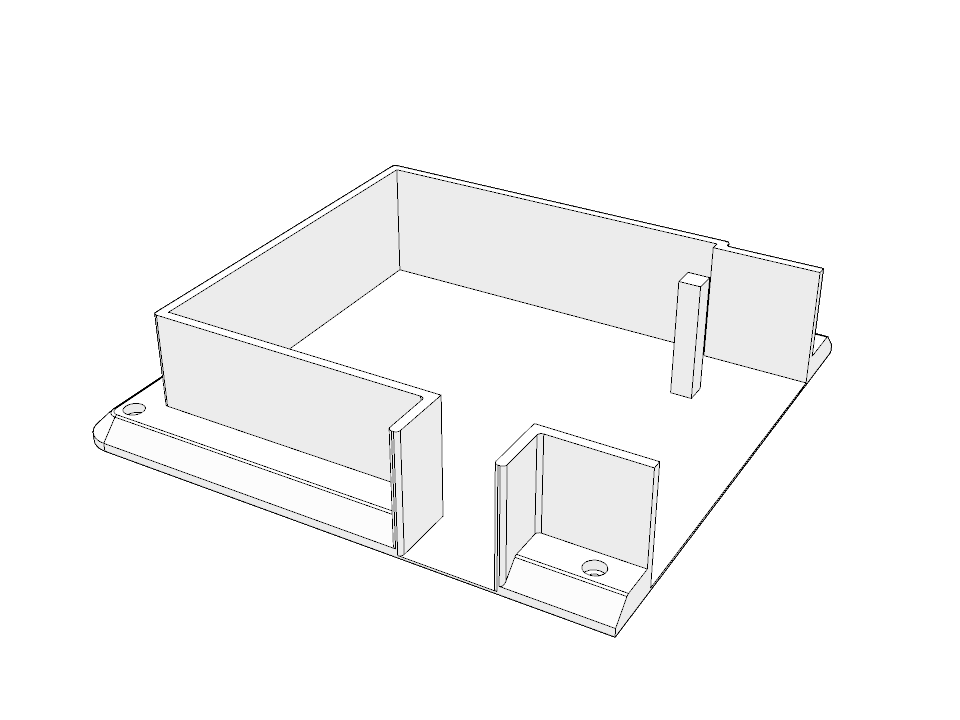

This is Level One of the TPM floor plan, featuring a detachable acrylic panel. The panel can be removed to allow users to place and reposition miniature objects on the floor plan, facilitating the planning and curation of the exhibition layout.

01

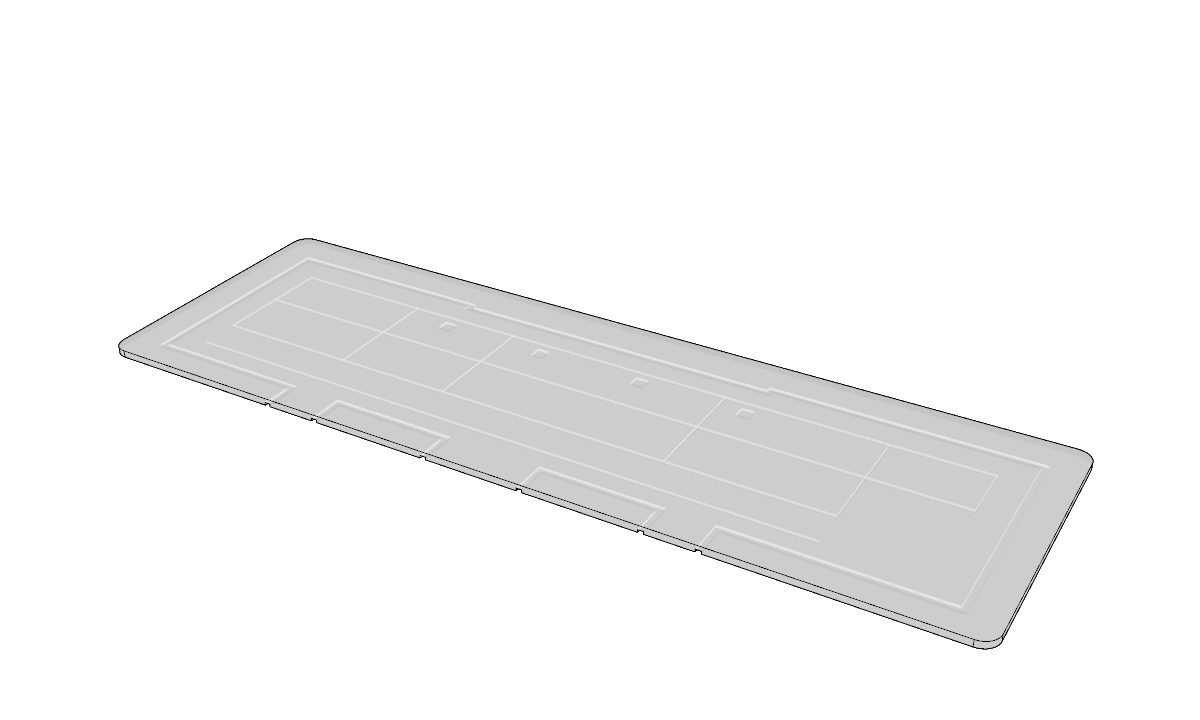

Detachable Acrylic Panel

This acrylic panel features the gallery’s lighting plan etched onto its surface. Its purpose is to help users visualise the placement of lighting within the gallery space, making it easier to plan and curate the exhibition effectively.

02

3D printed Floor Plan

This 3D printed floor plan design is modular and can be bolted and unbolted, allowing for updates in response to renovations or the incorporation of new, more permanent features within the gallery.

03

Wooden Panel

This wooden panel serves as the base of the entire floor plan structure. It provides foundational support, securing both the steel panel and the 3D-printed floor plan in place. Side handles are integrated into the panel design to facilitate easy transport.

Materials

3D Printed PLA

Stainless Steel Hardware

Wood Panel

Coated steel

Dimensions

800mm (Length)

250mm (Width)

650mm (Height)

Development Time

3 weeks

Design Goal

This is Level Two of the TPM floor plan, featuring a detachable acrylic panel.

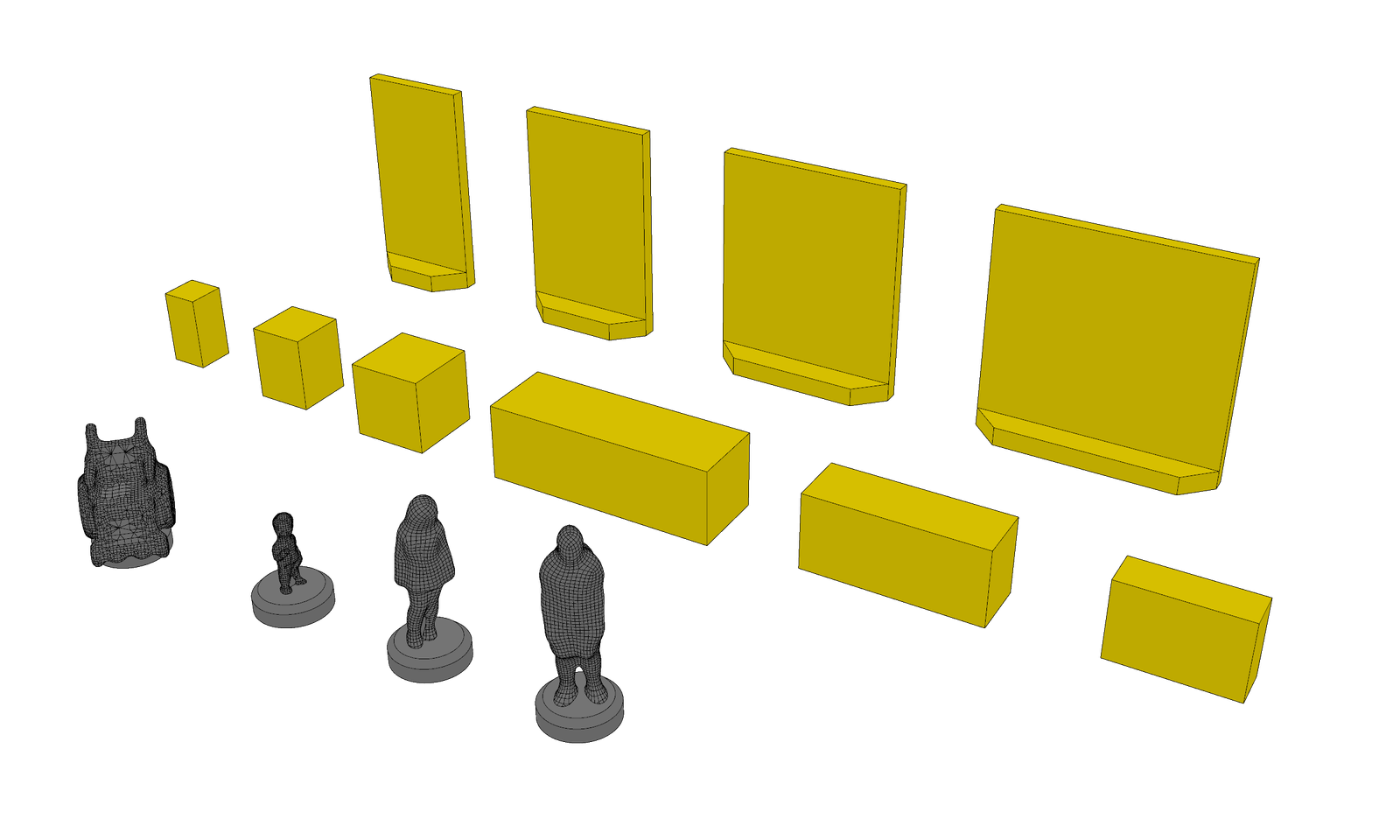

01

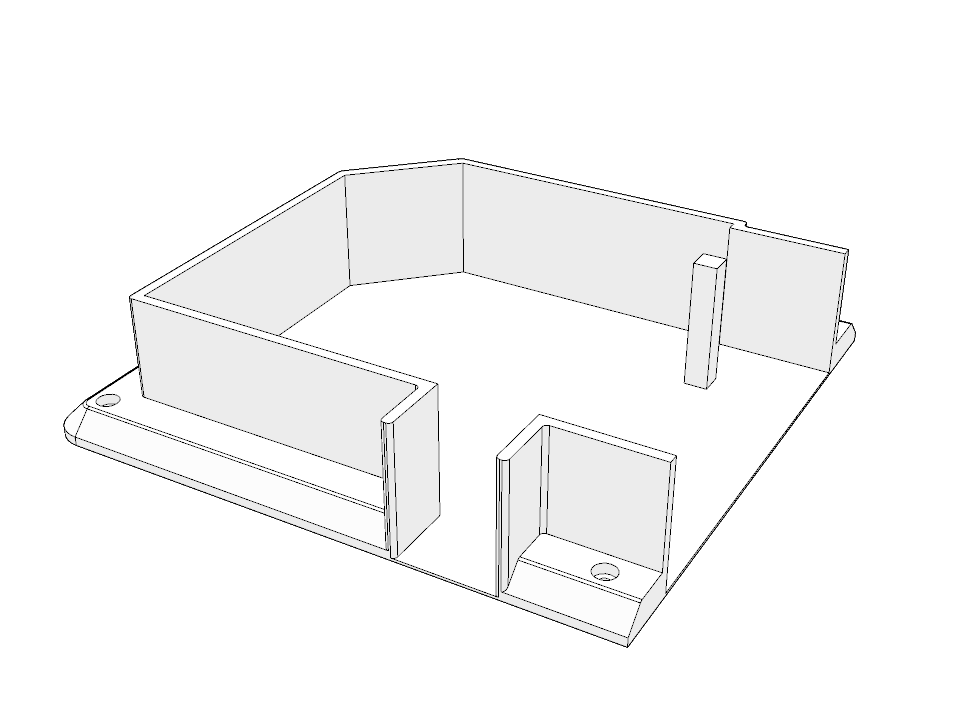

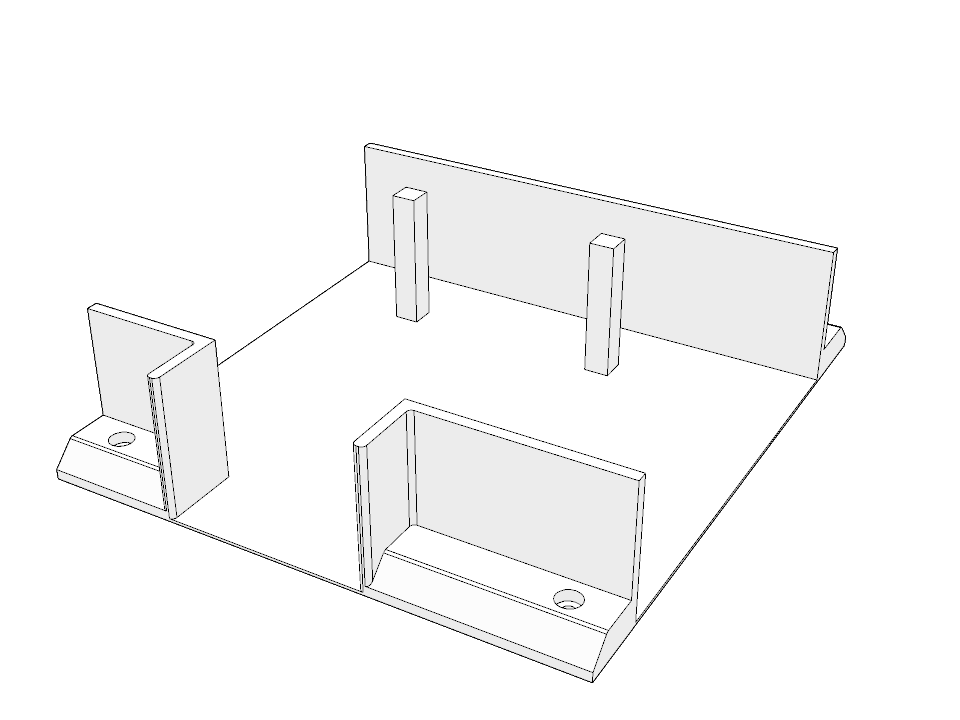

Mini Partitions

These miniature partitions are used to illustrate gallery sections or to assist in planning visitor circulation routes. They come in various sizes and feature chamfered corners, allowing them to be easily repositioned at 90-degree angles when necessary.

02

Mini Pedestals

These mini pedestals are scaled representations used to simulate the placement of display stands within the gallery space. Their compact form allows for flexible arrangement on the floor plan, supporting curatorial planning and spatial organisation.

03

Mini Figurines

These mini figurines represent a diverse range of visitors, including male, female, children, and individuals using wheelchairs. Designed to scale, they are used to simulate human presence within the gallery space, helping curators assess sightlines, accessibility, and the overall visitor experience.

Materials

3D Printed PLA

Magnets

Dimensions

Various

Development Time

3 weeks

Design Goal

These are miniature objects designed to be repositionable on the floor plan. Each object has a magnet embedded underneath, allowing it to securely attach to the magnetic floor surface. The models are built to a 1:500 scale.

1 x Level One (L)

1 x Level One (M)

1 x Level One (R)

1 x Level Two (L)

1 x Level Two (M)

1 x Level Two (R) x 1

Print Settings

Layer Height: 0.2

Wall Loops: 6

Top Layer: 6

Bottom Layer: 6

Advance Settings

Order of Walls:

Inner/Outer/Inner

Infill: 30%

Infill pattern: Gyriod

Temperature Settings

Nozzle: 200-210°

Bed: 50°

Total Print Time

20-30 Hours (Approximately)

Materials

PLA (Matte White)

1 x Acrylic Panel (Level 1)

1 x Acrylic Panel (Level 2)

2 x Coated Steel Panel

2 x Wooden Base Plate

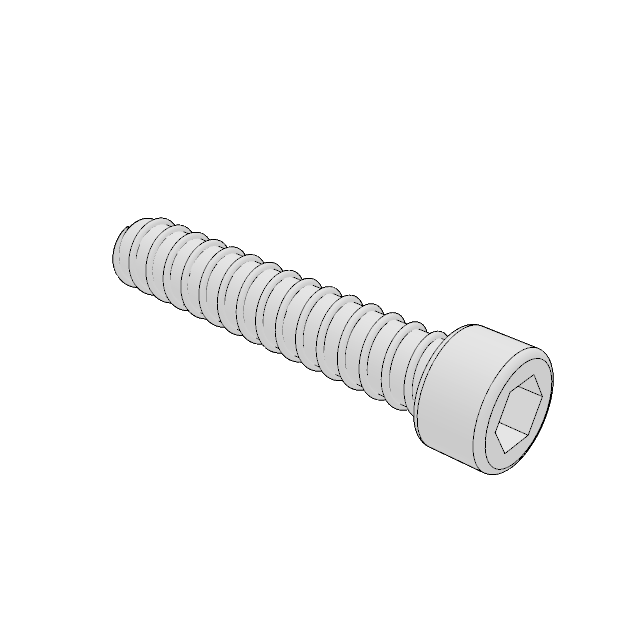

M4 Stainless Steel Bolts

15mm (x8)

22mm (x4)

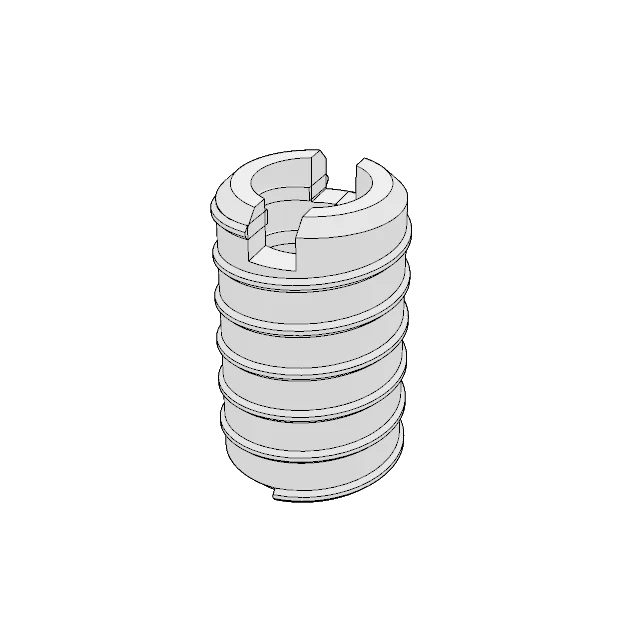

Stainless Steel Inserts

M4 x M8 X 6mm (x8)

M4 x M8 X 10mm (x4)

M52 Magnets

M6 x 2mm (x30)

M8 x 2mm (x20)

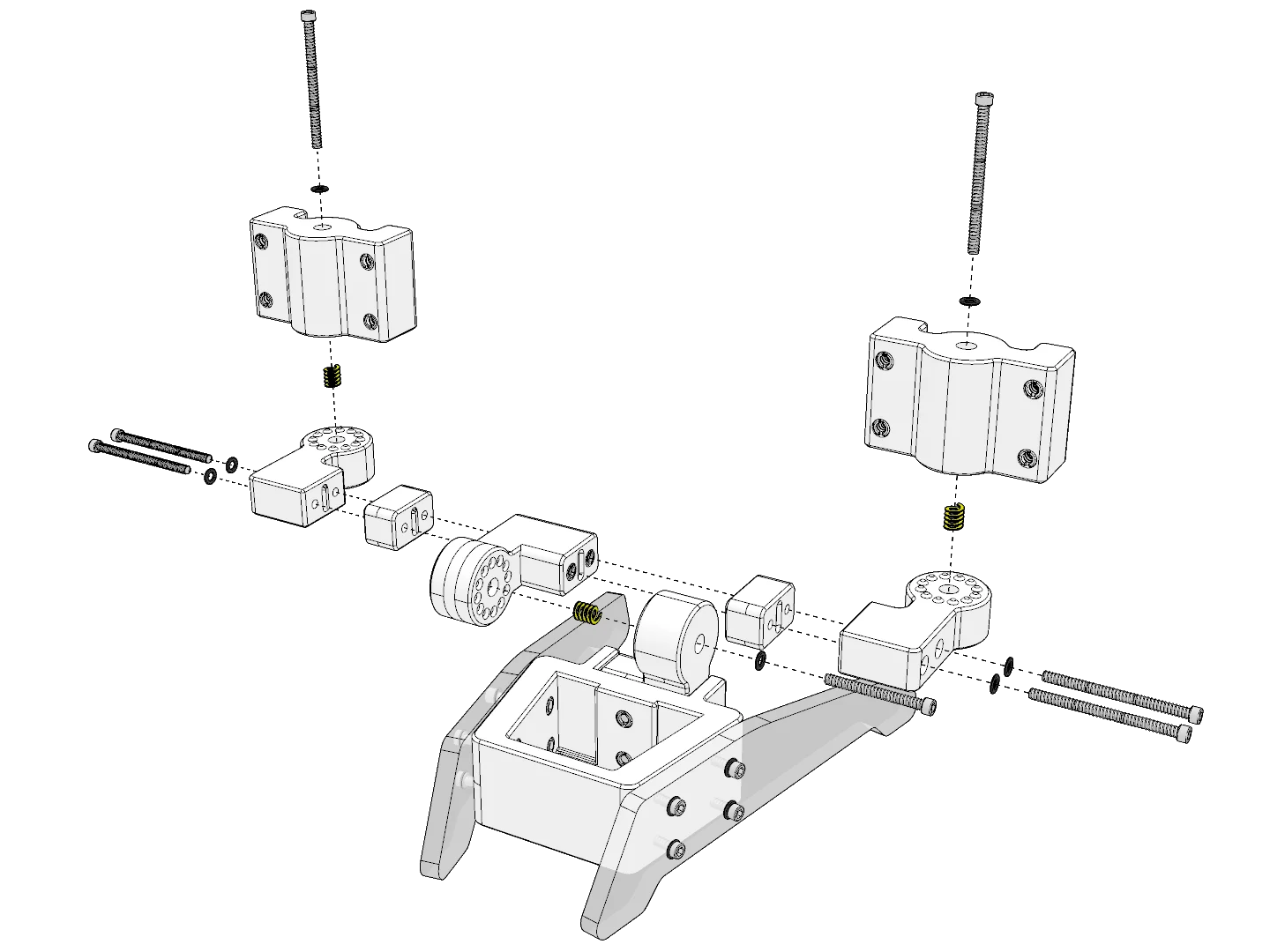

How to Prepare the Parts

This section outlines the process for inserting the stainless steel inserts into all the 3D printed parts necessary for the design assembly. It is important to complete this step before the assembly. Additionally, to ensure the stainless steel inserts remain securely embedded in the 3D printed parts, it is essential to use Maxi-Cure™ Extra Thick CA Glue for bonding plastics and metals.

How to Apply Maxi-Cure

Apply Maxi-Cure™ CA to one side of the parts to be joined, then press them firmly together for 10-20 seconds. For larger bonding surfaces, apply serpentine beads of the CA adhesive, ensuring sufficient spacing to allow for proper spreading. The adhesive will reach full strength within three hours. Clean the nozzle before securing the screw-on cap. To extend shelf life, refrigerate the product. Once cured, Maxi-Cure™ CA remains stable within a temperature range of -40°F to 220°F.

Steel Insert Holder

M4 x M8 x 6mm (x2)

Steel Insert Feet

M4 x M8 x 12mm (x4)

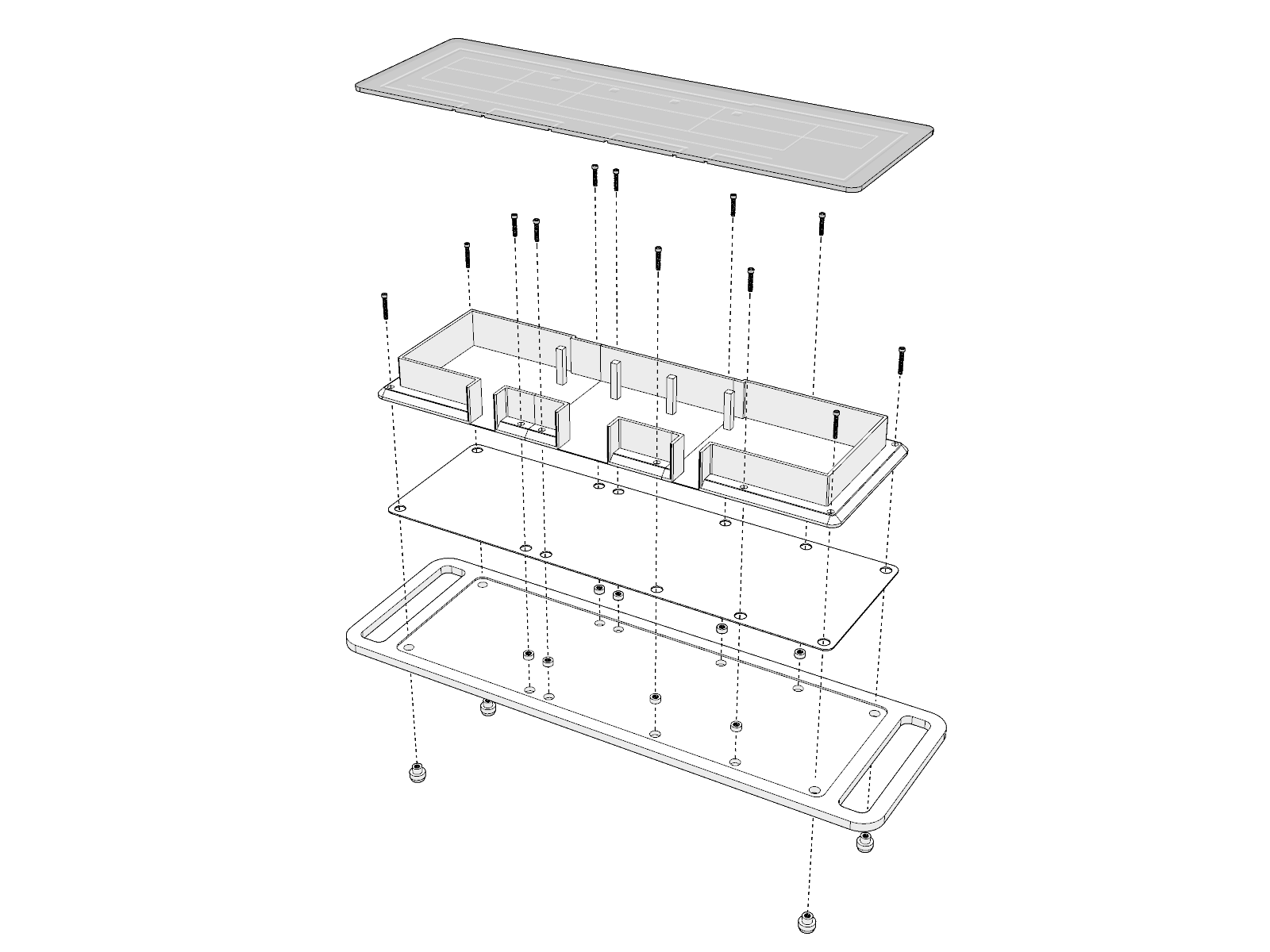

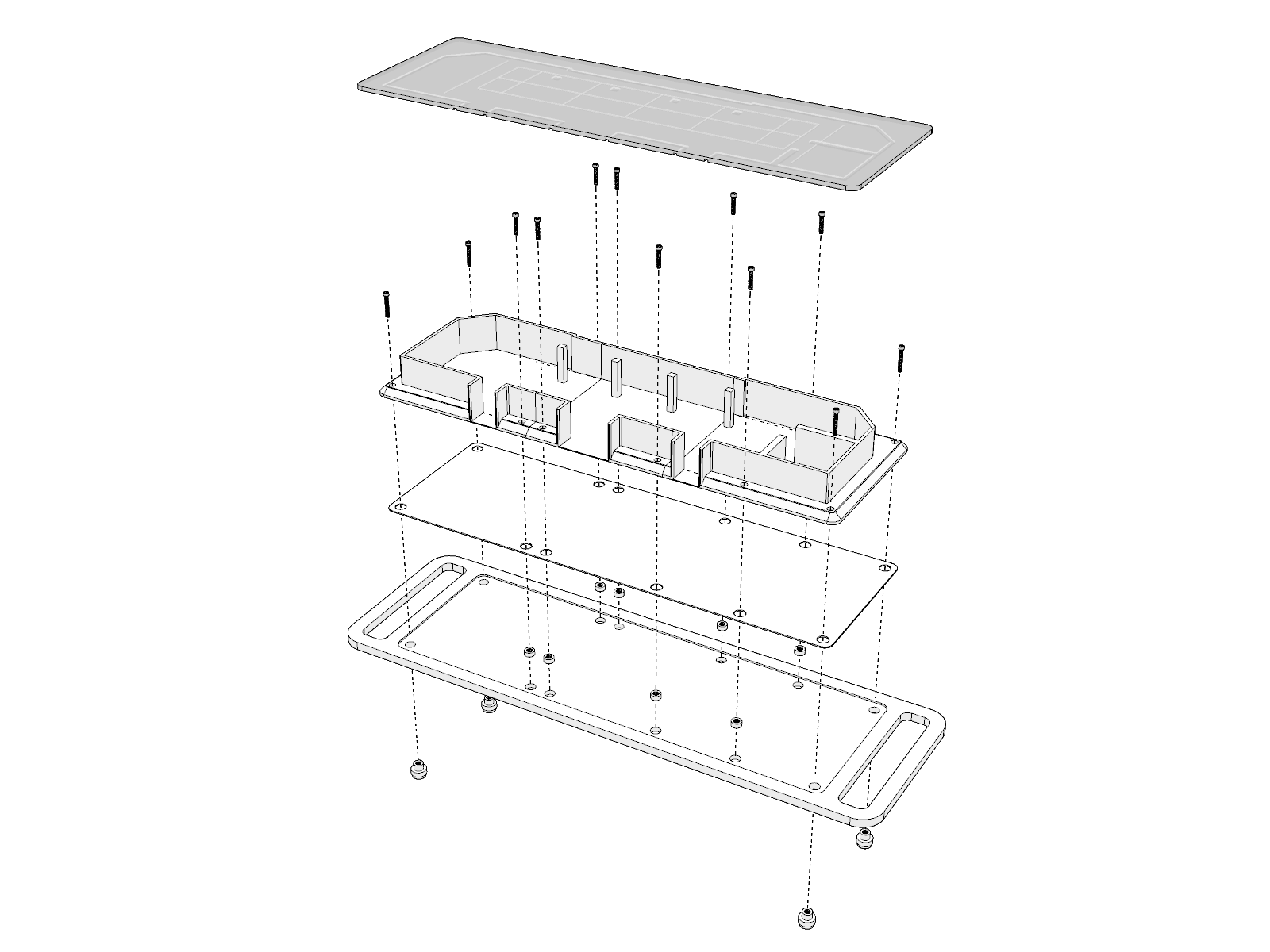

01

Glue Steel Insert Holders (x8)

Adhere the prepared steel insert holder into the cut holes of the wooden plane using the CA glue specified in the previous tab.

02

Glue Steel Insert Feet (x4)

Adhere the prepared steel insert feet are inserted from the bottom of the wooden base and glued to the wooden base using the CA glue specified in the previous tab.

03

Place Steel panel onto the cut out of the wooden base

Place Steel panel onto the cut out of the wooden base

Once all four steel insert feet and eight steel insert holders have been securely glued in place, position the metal panel into the cutout section of the wooden base.

04

Glue the 3D printed parts as shown above and place it on the wooden base.

Before inserting the 3D-printed parts into the wooden base, ensure that all holes on the printed components are properly aligned with the corresponding features on the wooden base.

05

Secure with M4 22mm Bolt

For all four steel insert feet, secure them by clamping the wooden base, steel panel, and 3D-printed part together in a sandwich configuration, as illustrated in the assembly diagram.

06

Secure with M4 16mm Bolt

For all eight steel insert feet, secure them by clamping steel panel, and 3D-printed part together in a sandwich configuration, as illustrated in the assembly diagram.

07

Place the Acrylic panel into the 3D printed perimeter of the floor plan

Place the Acrylic panel into the 3D printed perimeter of the floor plan

For this step, no gluing or hardware is required. Simply align the acrylic piece with the perimeter of the floor plan as shown.

01

Glue Steel Insert Holders (x8)

Adhere the prepared steel insert holder into the cut holes of the wooden plane using the CA glue specified in the previous tab.

02

Glue Steel Insert Feet (x4)

Adhere the prepared steel insert feet are inserted from the bottom of the wooden base and glued to the wooden base using the CA glue specified in the previous tab.

03

Place Steel panel onto the cut out of the wooden base

Place Steel panel onto the cut out of the wooden base

Once all four steel insert feet and eight steel insert holders have been securely glued in place, position the metal panel into the cutout section of the wooden base.

04

Glue the 3D printed parts as shown above and place it on the wooden base.

Before inserting the 3D-printed parts into the wooden base, ensure that all holes on the printed components are properly aligned with the corresponding features on the wooden base.

05

Secure with M4 22mm Bolt

For all four steel insert feet, secure them by clamping the wooden base, steel panel, and 3D-printed part together in a sandwich configuration, as illustrated in the assembly diagram.

06

Secure with M4 16mm Bolt

For all eight steel insert feet, secure them by clamping steel panel, and 3D-printed part together in a sandwich configuration, as illustrated in the assembly diagram.

07

Place the Acrylic panel into the 3D printed perimeter of the floor plan

For this step, no gluing or hardware is required. Simply align the acrylic piece with the perimeter of the floor plan as shown.

Stainless Steel Bolt ( M4 x 65mm)

Stainless Steel Bolt ( M4 x 65mm)

Stainless Steel Bolt ( M4 x 65mm)

Stainless Steel Bolt ( M4 x 65mm)

Industrial Spring ( M5 x M8 x 10mm)

P09 (Printed Part)

Assembly Reference

Completed Assembly (Iteration 02)

Phase One

In the initial phase, a 1:500 scale model was built and tested to assess the visual effectiveness of the wall heights, wall thickness, and overall miniature floor plan. The durability of key features, including walls and pillars, was also tested through appling pressure to ensure structural strength. These checks were essential before progressing to the next stage of the project, which involves the production of a wooden base plate and a magnetic plate for added functionality and stability.

Phase Two

With all key parameters confirmed, including scale and the mechanical properties of the PLA 3D print, the next phase focused on assembling the prototype. This involved mounting the 3D print onto a wooden base, with a anodised steel plate sandwiched in between for its magnetic features. The aim was to assess whether the wooden plate could withstand the weight of the bolted components, and to determine if the final prototype was too heavy or bulky for one person to handle easily.

Phase Three

Following the completion of phase two, a storage cart was constructed to house all floor plans and keep the miniature objects organised. Custom 3D printed modules were added to securely hold the miniatures, ensuring everything remains accessible and neatly arranged. The cart is fitted with lockable wheels for mobility and stability, and includes an attachment that allows two floor plans to be displayed side by side, supporting both storage and presentation requirements.